Concrete Expansion Joint Repair: Causes and Effects

If you have a concrete floor in your commercial building, you know expansion joints are necessary to allow for the natural expansion and contraction that occurs from temperature changes. Without these joints, large cracks can travel across your floor, creating costly damage. While your concrete floor expansion joints are designed to absorb and dissipate the stress from expansion, in extreme cases, the joints themselves can crack.

It’s necessary to understand that when the joints of your concrete floor do crack, they are actually working as they’re designed to, and protecting the slabs themselves. Replacement of cracked concrete slabs is costly and time-consuming, whereas replacing expansion joints in concrete is a much easier task. Once you detect cracked joints, it’s important to have them repaired quickly. Failing to do so can allow further cracking to occur not just in the joints, but in the concrete floor itself.

Replacing and repairing expansion joints in concrete slabs is a task best left in professional hands. Attempting to fix a failing expansion joint in a concrete floor without having the right knowledge, materials and tools can lead to increased damage and unnecessary costs. Hiring a professional company to assess your expansion joint repairs is your safest and wisest course of action. It will also identify the cause of failure of the expansion joints. This way, you can take steps to prevent future damage.

Houck is dedicated to safety, quality, and performance. With years of experience in the industry, we have the solutions you need for your concrete floor maintenance and repair. For expansion joint repair you can trust, contact us today!

What Causes Expansion Joints in Concrete to Crack?

The biggest factor that causes expansion joints in concrete to crack is temperature. Almost always, premature cracking is due to poor planning and wrong material choice. Engineers design expansion joints to accommodate movement due to physical forces resulting from temperature fluctuation. That includes expansion reactive forces when the temperature rises and contraction forces when temperatures drop.

Concrete is a complex building material. Engineers specializing in concrete construction spend considerable time learning its properties in order to pour slabs built to withstand temperature changes. A main concrete design technique is to specify controlled expansion joints at specific intervals, which factors in specific expansion joint materials that work in conjunction with the poured-in-place concrete slabs.

People unfamiliar with concrete might think this hard substance is basically inert, but that’s far from reality in the concrete construction business. Concrete is a predictable substance. Its physical properties and tolerances are well known to experienced engineers.

Concrete moves at a precise rate in relationship to ambient temperature. There is a thermal expansion coefficient of 0.0000055 per linear inch of concrete per 1 degree Fahrenheit of temperature change. Engineers compensate for anticipated concrete movement to determine expansion control joint width and placement. The thickness of a concrete placement is not a factor. Concrete reacts uniformly on a linear movement regardless of how thick a slab might be.

For instance, 100 linear feet of concrete flatwork at 100 degrees Fahrenheit has an expansion factor of 0.66 inches. If you raise the same size slab’s temperature to 160 degrees Fahrenheit, its expansion factor will be 1.06 inches. To set the example, think of a concrete roadway. A mile of concrete has an expansion factor of 34.85 inches at 100 degrees, while the expansion factor of the same mile at 160 degrees is 55.76 inches.

This is why there are so many expansion joints in concrete highways. The continual expansion and contraction actions from hot and cold cycles are hard on the joint material. The continuous movement causes fair wear and tear resulting in high maintenance costs and early joint failure.

The same situation occurs with the concrete floor in a commercial or industrial building, albeit at a smaller scale. There is a proportional relationship to expansion joints in concrete floors. Engineers estimate the temperature range fluctuations expected in a building, then mathematically calculate expansion joint interval spacing and the width of the joint. They also calculate the best material options for filling the expansion joint.

The second leading factor causing concrete expansion joints to crack is poor material selection for the joints themselves. Expansion joint materials have to be compatible with the type of concrete they’re paired with. Joint materials also have to withstand the environmental conditions they’re destined for.

Many different concrete mix formulas are available. Depending on the application, some concrete mixtures are high in corrosive additives, like calcium and fly ash. These chemicals can be highly destructive on expansion joint materials if they’re not suitably selected. Also, certain concrete expansion joint materials aren’t designed for environments where oil, fuel and other volatile contaminants cause the material to fail.

To understand more about why expansion joints in concrete fail and crack, it’s helpful to know what joint materials are commonly used. It’s also good to know each material’s properties, so you don’t make the mistake of repairing or replacing your expansion joints with the wrong substance.

Commonly Used Concrete Expansion Joint Materials

If you look at your current slab’s expansion joints, you’ll certainly recognize the shape, color and texture. But, you might not know the material and whether it’s properly suited for your building environment. These are the most common expansion joint materials used in concrete slab construction and situations where they’re best suited:

- Asphalt Expansion Joints: Asphalt is the most commonly used expansion joint material used in concrete flatwork. Asphalt is a self-sealing material, so it rarely requires an additional sealer. It stands up well to petroleum spills and harsh cleaning products. It is a non-absorbing material and protects well against water infiltration. You’ll often find asphalt expansion joints in outdoor and high-humidity environments.

- Fiber Expansion Joints: Fiber expansion joints are an advanced form of standard asphalt joint fillers. They are composed of cellular fibers chemically bound by liquid asphalt and then cooled into semi-solid form. The material is very flexible and versatile with excellent memory properties to resist continual expansion and contraction forces. Fiber expansion joints work well in both indoor and outdoor applications.

- Ceramar® Expansion Joints: Ceramar® is an expansion joint filler made of flexible foam. It’s a brand-name filler composed of tightly enclosed cellular structures blended with isomeric polymers. Ceramar® is recognizable from its distinctive light gray color. It’s easy to install, highly flexible and has an extremely high memory rate. It also reacts well with most commercial caulking and sealants. Ceramar® is a popular choice across the board.

- Sponge Rubber Expansion Joints: Sponge rubber material is highly suited to applications where temperatures rapidly change. Sponge rubber is a chemically manufactured product with tremendous elasticity. It also has high heat and cold resistance, making it an excellent expansion joint material in buildings ranging from foundries to cold storage warehouses.

- Cork Expansion Joints: Cork is a naturally occurring organic product harvested from cork trees. It is one of the most resilient expansion joint products available. Manufacturers mix granulated cork with phenolic resin to produce joint material that’s incredibly flexible and durable. One popular form is self-expanding cork that works well with rapidly contracting slabs such as freezer settings. Cork will stretch well beyond its inert state without breaking its bond to adjacent concrete materials.

- Plastic Expansion Joints: Plastic also has its place as a concrete expansion joint material. Although most plastic expansion joint products don’t lend well to flexing, plastic can be an ideal material in temperately-stable environments. Plastic joints are aesthetically pleasing compared to some other choices making them popular in showrooms and assembly plants where cleanliness is important. Popular plastic expansion joint brand names are Speed-E-Joint®, Deck-O-Joint®, Snap Cap® and Keyway®.

Long-Term Benefits of Concrete Expansion Joints

Keeping your concrete expansion joints in pristine condition has many benefits. Over the long term, buildings and other concrete slab structures with properly designed and maintained expansion joints combined with compatible joint-filling materials will perform without issues. Properly sealed and maintained expansion joints should perform as intended. They should not be a liability nor an ongoing expense.

As a building owner or manager who depends on concrete slabs for production or storage, you have better things to worry about than problems with concrete expansion and contraction. If you have the correctly designed and filled joints, you’ll find several benefits for your business. The long-term benefits of concrete expansion joints include:

- Peak Performance: Properly maintained, repaired or replaced concrete expansion joints perform at their peak by allowing slabs to naturally expand and contract according to any temperature fluctuations you can expect. There will be no damage from buckling or splitting.

- Excellent Hygiene: Expansion joints that remain sealed offer excellent hygiene benefits. They keep joint cracks closed and impervious to contaminants getting inside tight spaces. This is especially beneficial if you’re in the pharmaceutical or food and beverage industries, which must adhere to high sanitary and hygiene standards.

- Economic Return: You can expect economic benefits from having the right expansion joints and materials. If built, repaired or replaced properly, your joints should provide years of service with no cash layout. A sound investment in expansion joint maintenance and repairs allows you to reserve your operating capital for future investments in your business.

- Superior Safety: Without question, professionally designed or repaired expansion joints give superior safety for your employees. Good expansion joints in concrete slabs minimize tripping hazards. They make forklift travel smoother and reduce the jarring effect that poorly built or maintained expansion joints deliver.

- Low Maintenance: Professional concrete expansion joints deliver you the big benefit of being low maintenance. If you have your expansion joints installed, repaired or replaced by a professional company that specializes in expansion joint work, you’ll definitely lower your maintenance work in the long term. In turn, that makes your workplace perform at its peak with excellent hygiene and superior safety for the clear benefit of a positive economic return.

For expert concrete expansion joint repair, choose Houck. Contact us today!

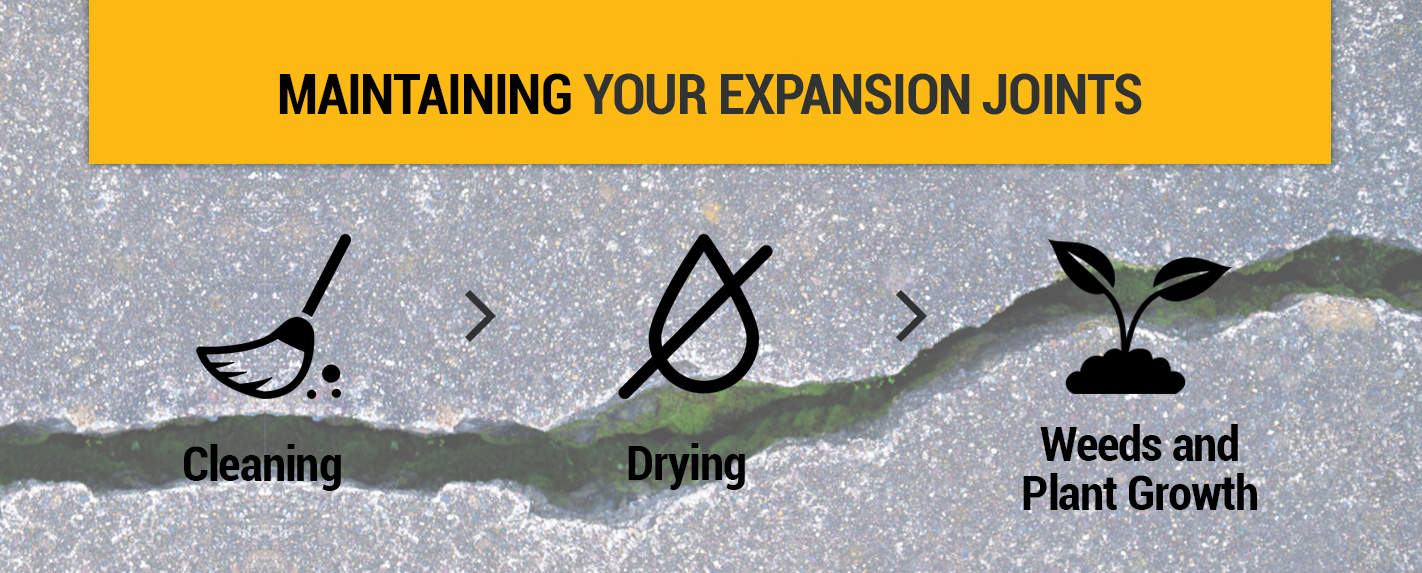

Maintaining Your Expansion Joints

Properly maintaining your expansion joints is the key to ensuring long-lasting performance. Preventive maintenance will help delay any repairs that may naturally need to be done over time and give you longer life out of your expansion joints. Regularly inspecting the state of your expansion joints will ensure you catch a problem right away. As you conduct regular inspections, you’ll notice issues and be able to remedy them right away.

There are steps you can take to keep your concrete floor expansion joints in healthy condition, including:

- Cleaning: Keep dirt and debris out of your expansion joints. Debris can encourage moisture to seep into your expansion joints, causing them to crack.

- Drying: Don’t allow standing water to remain on your expansion joints for too long. Always remove water so it doesn’t penetrate below cracks and under your concrete floor slabs.

- Weeds and plant growth: If you see weeds and plants growing in your expansion joints, remove them immediately. Their roots can quickly cause damage to your joints and flooring system.

If you discover cracks in your joints, the process of replacing expansion joints in a concrete floor is relatively simple. You need to choose the right joint filler to create a new expansion joint that is both strong and flexible.

Never fill your cracked expansion joints with concrete. This removes their flexible nature and can cause your entire floor to crack. Instead, apply an industrial concrete floor caulking or filler designed to resist cracking, allow for concrete expansion and resist water penetration below your floor.

When to Repair Cracked Expansion Joints

The best time to repair cracked expansion joints is as soon as you’re aware of the problem. In most situations, this won’t be a sudden event requiring your immediate attention. Instead, expansion joints crack slowly and steadily. It’s much the same way that concrete expansion and contraction itself is a slow and steady process.

Regardless, you should still be aware of the first signs of cracked expansion joints that require repair, including:

- Hairline cracks developing into larger caverns

- Pieces of expansion joint material beginning to loosen and dislodge

- Discoloration and water retention during regular cleanups

Don’t wait until little situations become a big problem — repair cracked expansion joints the moment they’re evident. It’s a decision that’s safer for your workers, cleaner for your products and financially sound.

The question isn’t whether to take action — it’s what action to take. That’s the decision of whether to simply repair your existing concrete expansion joints or to remove them entirely and replace them with the right products. If you decide on removing them, then it’s critical to have the new ones installed by the best professionals in the concrete expansion joint business.

Ultimately, it’s your choice in what to do. The important thing is to make the right choice and to make it with the best information. This is why Houck is your best choice for both replacing and repairing your concrete floor expansion joints.

Replacing and Repairing Your Concrete Floor Expansion Joints

Whether you’re replacing or repairing your concrete floor expansion joints, it’s crucial to contact an expert in the field. Working with a team of professionals ensures you’re getting the best service possible and that the job is getting done correctly and safely. When you do it yourself, you risk making beginners’ errors that could be costly to undo in the long run.

At Houck, we have a commitment to safety, quality, and performance. With years of experience in the industry, we have the solutions you need for your concrete floor maintenance and repair. We can complete all of your industrial and commercial floor repairs. Call our professional team today and we’ll make sure your expansion joints are properly repaired and ready for years of use.